Specification

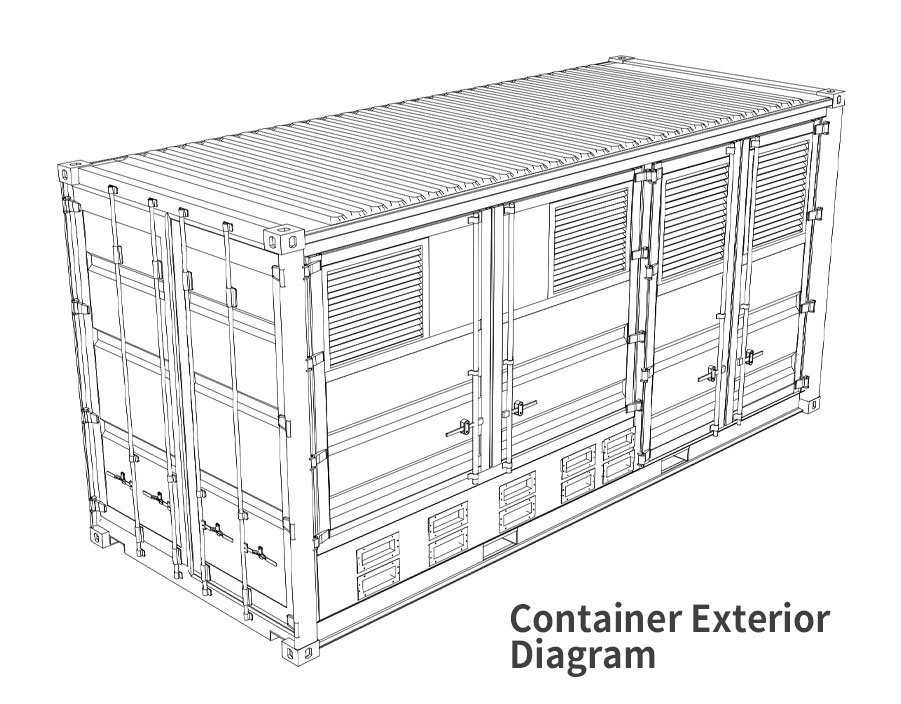

The PV BOX adopts a standard 20-foot-high container.Internal/external color of the container: RAL7001 silver gray paint.

- The surrounding door panels, corrugated wall panels, and roof panels are made of SPA-H weather-resistant steel.

- The four vertical columns of the container are made of SPA-H weather-resistant steel.

- The interior sealing panels are made of SPA-H weather-resistant steel.

- The bottom crossbeam is made of SPA-H weather-resistant steel.

- The bottom side beam is made of Q235B material (Q235B is low-carbon steel).

- The interior floor patterned steel plate is made of Q235 material (Q235 is ordinary carbon structural steel).

- The total paint film thickness on the outside is 280 µm (rich zinc primer 80 µm, intermediate paint 120 µm, polyurethane topcoat 80 µm).The inner paint has a total film thickness of 140 µm (rich zinc primer 50 µm, intermediate paint 50 µm, epoxy topcoat 40 µm), and the outer paint is polyurethane two-component topcoat RAL7001.The inner paint is epoxy two-component topcoat RAL7001, and the bottom has a total film thickness of 280 µm (rich zinc primer 80 µm, asphalt paint 200 µm).

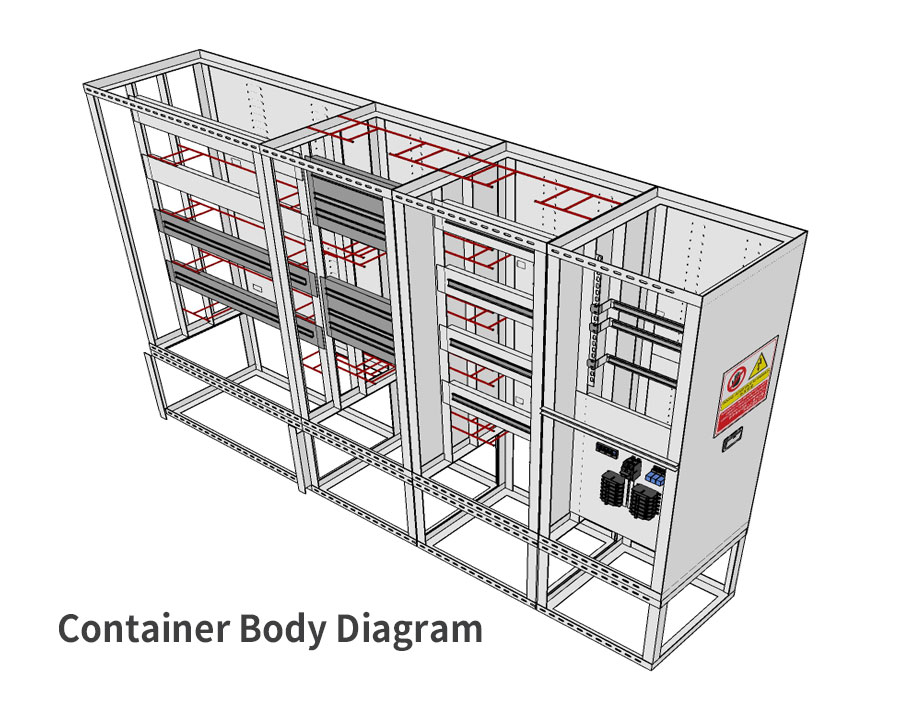

Product Structure Exploratory Diagram

Information Protection Statement

Our company highly respects the privacy rights of our clients. We comply with the Personal Data Protection Act of the ROC and relevant regulations regarding the collection, processing, and utilization of customer information. The collection of personal data is primarily aimed at improving service quality and enhancing personalized services (including providing sales information that is suitable for you). We guarantee that your personal data will not be disclosed to any third party unrelated to our services or transactions without your consent or for purposes other than those mentioned above. The personal data you provide may be collected by relevant product providers for the purpose of providing subsequent related services.